More and more I find I prefer integral tenons to using Delrin–mostly because it affords the most flexibility for shaping, especially when shaping saddle stems close to the shank. I have cut into the Delrin many times while trying to refine a shape on a stem using a Delrin tenon. Once I developed the skills for cutting integral tenons I found using them provides just as good a fit and feel as Delrin. Still, both integral and Delrin tenons each have there own advantages, depending on the design of the pipe. The following is the procedure I use for cutting integral tenons.

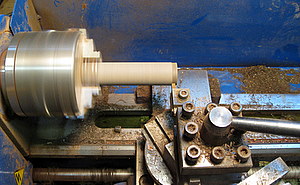

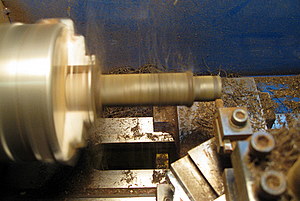

I first rough in the rod stock to the largest diameter I want for the stem at hand:

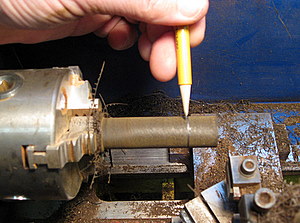

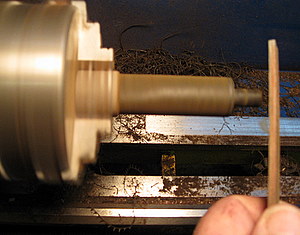

Next I measure how long the tenon needs to be.

Now I transfer that to the rod stock. If I’m adding any insert materials, I would also account for there here, but that is not the case here. I also leave a little extra room for find tuning the tenon to the mortise:

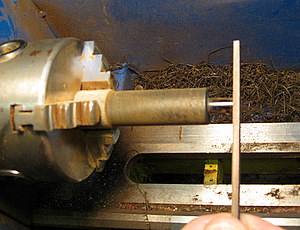

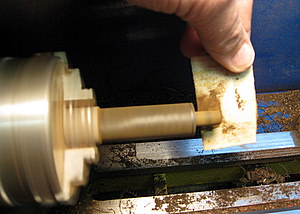

Now I start cutting the tenon. I’ve found using a very sharp HSS steel tool is far better than carbide, which simply cannot get as sharp as one needs to cleanly cut ebonite:

I take heavier cuts at first, and then smaller and smaller cuts as I get closer to the final diameter:

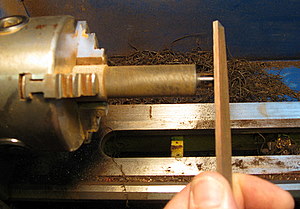

Once I get close, I stop and measure ofter to make sure I have plenty of room to sand to the final diameter:

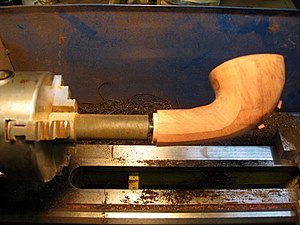

When I get close to the final diameter I want to check it with the actual stummel. First I round the edge so as not to damage the mortise:

Then I sand it smooth:

I then check the fit, and re-sand as needed to get the fit just right. I end up with 400 grit and then steelwool:

Once I get the fit just right, I face off where the stem will meet the shank:

Now I check for the length of the tenon in the mortise:

And adjust until it fits perfectly:

At this point we can drill the stem. I drill integral tenons the same way I drill Delrin.