I now have the stem drilled and fit to the stummel:

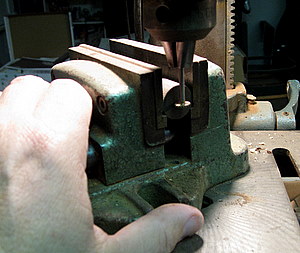

Now I can cut the slot and do some of the rough shaping in preparation for shaping it with the stummel. The first thing I do is cut the slot using a small Dremel rotary saw (3/8 inch and cuts a 1/16″ slot, part #199). It can be ordered here. I used to do this freehand with the dremel tool, but have had much better success using the tool chucked into the drill press with the stem secured in the drill press vice. First I adjust the table to the exact right height:

and then pull the vice and stem sliding on the drill press table into the spinning bit. It takes a little practice to get the hang of it.

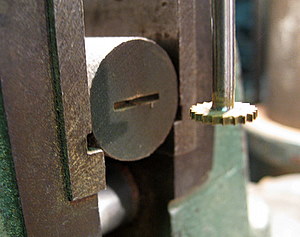

Next I funnel the airway from the slot evenly into the airway using a 1/16″ dill bit slurred back and forth across the width of the slot. Great care must taken to keep this as even and flat as possible. This removes the bulk of the material between the front of the slot and the wider part of the airway in the stem, but I’ll still need to do lots of have file work to get a nice even flow to the funnel.

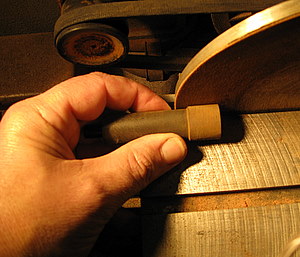

Next I rough in the shape of the stem using a disk and belt sander:

A lot of what I can do at point this depends on the final design of the stem and pipe. I’ve found it’s helpful to have a roughed in button and a start to the taper or saddle, but stay well away from the tenon end where I could mess up the fit with the stummel. I leave plenty of meat for adjusting the shape and like doing nearly all of that while attached to the stummel.