With the tenon correctly fit to the mortise I can now drill the stem.The drilling operation I use is essentially the same for Delrin tenons or integral tenons. I use a center drill/countersink first to ensure a nicely centered and secure start to the drilling operation, as well as providing a nice counter sunk draft hole:

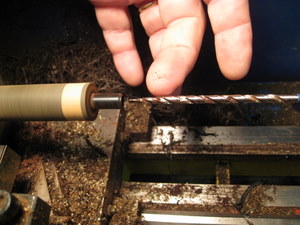

Next I measure for the depth of the first drilling. Shown is a 5/32″ tapered drill, which does an excellent job of drilling. The 5/32″ tapered bit also provides an open draw while tapering down to a smaller hole. I stop this drilling about 1/2″ to 3/4″ short of the end and then follow with a 1/16″ drill on through the stem. This last section near the bit is then flattened out and funneled wider to provide for a continuous airflow, and yet facilitate a thin comfortable bit:

The drilling is done very slowly in terms of speed and feed rates, and the drill removed often to cool and clear chips. The drill should not be too hot to touch. If it is, it could start to melt and distort the ebonite.

Next I change to the 1/16″ drill, and drill completely through the stem. Again, this must be done very slowly and the drill removed to clear chips:

Next I sand the draft hole though most of it’s length by wrapping sandpaper around the 1/16″ drill bit. The final 3/4″ or so cannot be reached, but it will be carefully opened, filed, sanded, and buffed later by hand. Steel wool does a nice job cleaning up the tenon end after the sanding.

Here we see the tenon finished, and then the final check with the stummel:

And next the fun really begins!