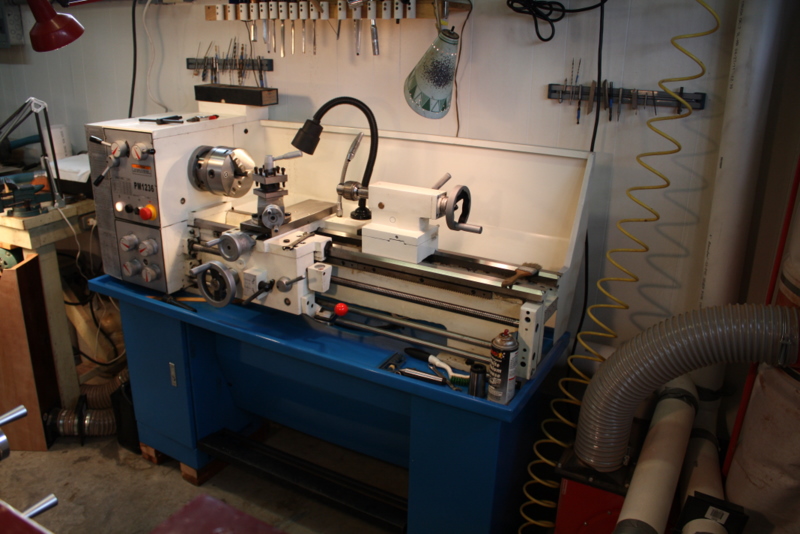

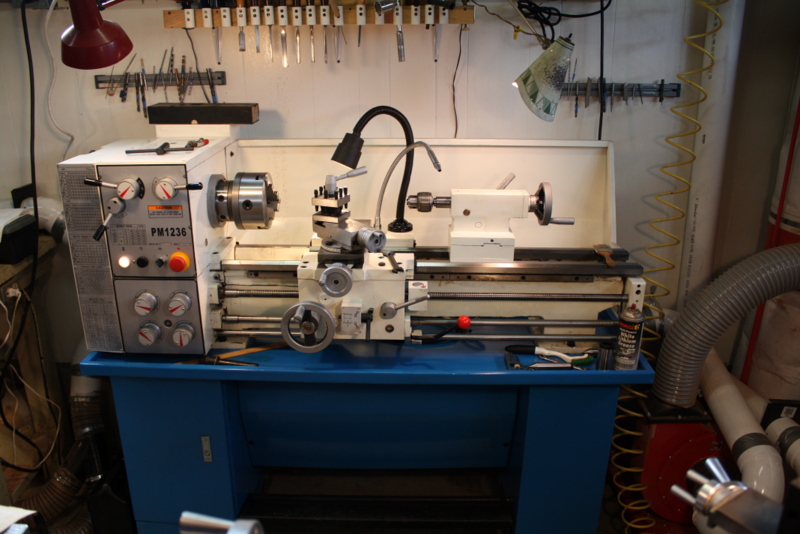

In Summer and Fall 2011 I was able to make a lot of exciting improvements to the workshop. First I upgraded the electrical service adding three dedicated 220V circuits for my compressor, dust collector, and my long awaited lathe, a Precision Matthews PM1236, which arrived in November after a 6 month wait! Also added lots of 20A 110 circuits. No more running into the house after throwing a breaker! In preparation for the new tools I also did some painting, ran dust collection pipe and hose and compressed air lines to several different work stations. I also had to re-organize the shop to fit the new lathe and added a 2HP 3600 RPM motor for 36 grit wheel while retaining the 1750 motor for finer grits and buffing. I also built a separate free standing briar rack.

In March of 2010 I added the 36 grit wheel after visiting with Todd Johnson and Bruce Weaver for a few days. I now spend a great deal of my pipe making time at that station. The dust collection box is attached to my shop vac for now, but I have hopes of replacing that with a full blown dust collector soon . And I’d love to replace my 9×20 lathe with a Precision Matthews 1127VF sometime in 2011 (see above, yay!).

In Summer 2009 I reorganized after replacing the dilapidated garage door with a new insolated door that has a row of windows, so I have much more natural light. Included in the improvements was a new bench/cabinet, which was scrounged from one of the old science labs decommissioned at Murray State. I had to add a top, a side, and a back, but it’s maple with dovetail joints so it should hold up well. I also made a rack and a new shelf for lathe tools.

A bit dated now, but looking down on the shop from the kitchen door. I miss that leather chair! But, I gained a four wheel dedicated buffer setup over there, along with a separate bench for cleaning up estate pipes.

Looking at the piano workbench area to the right, and the briar rack, sander/buffer stations toward the left.

Open briar rack, buffer and sander station.

Closed briar rack, buffing and sanding station.

Looking down the tool lane (left side). The first wheel runs at 1725 RPMs and 3/4 HP. I use it for sanding (220 grit up through 600 grit), and buffing. The second wheel runs at 3450 RPMs and 2HP. That one is dedicated to a fiber backed 36 grit wheel. I can really lean into it to remove material fast if needed without it bogging down at all. My beloved PM1236 is down from those, and then the dust collector.

Looking down the tool lane (center)

Ebonite and cumberland rod storage between the compressor and briar rack.

Looking down the tool lane (right)

Old Harbor Freight lathe and drill press on the repurposed chemistry lab cabinet I scrounged from the University.

My beloved Precision Mathews 12×36 gear head lathe

Another shot of my wonderful lathe!

Have I told about my lathe yet? You know you want me to 😉

Dust Collector. I ran 6″ PVC pipe to the various stations. It works great! Don’t procrastinate emptying the bag, though. Briar dust and especially glass beads from the sandblaster get heavy fast! It’s well over 200 pounds when it’s less than a third full.

My old table saw, which I retired and gave to a friend. Replaced with a Delta jobsite saw that I can set up when I need it.

Old Harbor Freight 9×20, which I hate. It’s awful. I’ve dedicated it to prepping Delrin tenons.

My old Harbor Freight Lathe, drill press, and bandsaw.

Blasting station. I have since built a new custom workbench for it with tool storage underneath.

Blasting cabinet. I have added an LED light that sits on top shining straight down through the plastic. It really helps, but I’ve got improve how quickly the plastic protection clouds up.

This wonderful old case holds some old pipes I don’t smoke often. Some of my earliest handmades, and some estates, as well as part of my tobacco cellar.

Another messy spot. And actually, I have changed it a good deal. I have a very small lathe on top of that book shelf, and lumber racks above it.

My beloved workbench, which is now where my old table saw used to be.

My desk area. The workbench to the left I made years ago is now in a different spot. I have my keezer there now. You can see the doorway just up the stars into our kitchen.

I do most of my hand work here. The plastic drawers that contained sandpaper are no gone. I now store sandpaper in hanging file folders mounted on the side of the piano (ahem) workbench.

The messy corner. OK, one of the messy corners 😉

Volcano stummel in progress